The Future of High-Power Wind Generators

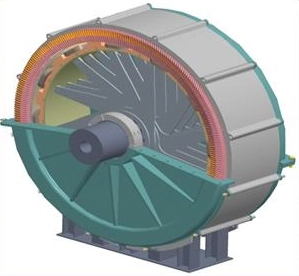

Hyper Tech’s low AC loss MgB2 superconductors have enabled the development of all-superconducting, rotor and stator, high power 15-20 MW wind turbine generators with higher efficiencies.

The Challenge: Scaling Up Wind Energy

Harnessing wind energy provides an alternative to consumable fuel resources. Land based and offshore wind energy farms are becoming more desirable; however, larger power blades and towers are needed to meet growing demand for this power source and for the equipment to be viable offshore. Current low power (2-7 MW) wind turbine systems use a gearbox, which becomes too large and heavy as tower size and power increase.

The Risk of Permanent Magnet Generators

For higher power the offshore wind industry is pursuing the development of rare earth permanent magnet (PM) based direct drive turbine generators rated at 12-15 MW; these would weigh over 400 tons each and cost well over $5M (for a 15 MW PM based system).

The wind energy industry will be at risk if turbine technology is solely based on PM materials because over 90% of the world’s rare earth PM market is controlled by one overseas country.

The Superconducting Advantage

An alternative solution for the wind industry is wind turbine generators free of rare earth permanent magnets using superconducting (MgB2) technology.

An MgB2 superconducting direct drive generator will minimize tower size and weight by substituting heavy iron with lightweight composites and will increase the power density of the wind turbine. Equipment reliability increases because of a more simplistic generator rotor design. Another advantage of using MgB2 generators for offshore projects is that the unit could be repaired onsite without being removed from the structure.

Hyper Tech’s low AC loss superconductor wire has removed the barriers to developing an all-superconducting, rotor and stator, high power wind turbine generator that is less costly than machines based on rare earth PM material.

The Future of High-Power Wind Generators

Hyper Tech’s low AC loss MgB2 superconductors have enabled the development of all-superconducting, rotor and stator, high power 15-20 MW wind turbine generators with higher efficiencies.

The Challenge: Scaling Up Wind Energy

Harnessing wind energy provides an alternative to consumable fuel resources. Land based and offshore wind energy farms are becoming more desirable; however, larger power blades and towers are needed to meet growing demand for this power source and for the equipment to be viable offshore. Current low power (2-7 MW) wind turbine systems use a gearbox, which becomes too large and heavy as tower size and power increase.

The Risk of Permanent Magnet Generators

For higher power the offshore wind industry is pursuing the development of rare earth permanent magnet (PM) based direct drive turbine generators rated at 12-15 MW; these would weigh over 400 tons each and cost well over $5M (for a 15 MW PM based system).

The wind energy industry will be at risk if turbine technology is solely based on PM materials because over 90% of the world’s rare earth PM market is controlled by one overseas country.

The Superconducting Advantage

An alternative solution for the wind industry is wind turbine generators free of rare earth permanent magnets using superconducting (MgB2) technology

An MgB2 superconducting direct drive generator will minimize tower size and weight by substituting heavy iron with lightweight composites and will increase the power density of the wind turbine. Equipment reliability increases because of a more simplistic generator rotor design. Another advantage of using MgB2 generators for offshore projects is that the unit could be repaired onsite without being removed from the structure.

Hyper Tech’s low AC loss superconductor wire has removed the barriers to developing an all-superconducting, rotor and stator, high power wind turbine generator that is less costly than machines based on rare earth PM material.