Protecting the Grid, Enhancing Reliability

Advanced FCLs for Grid Protection and Efficiency

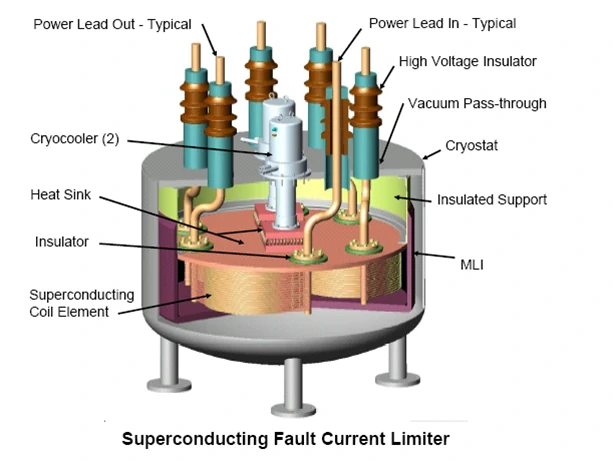

Hyper Tech is developing two types of fault current limiters (FCL), devices installed on the electric power grid to improve the reliability of delivering electricity to customers: one is non-superconducting for distribution level voltages, and a second type is a superconducting version for high voltage transmission.

The Challenge: A Modernizing Grid

Many of the components on the U.S. electrical grid (transformers, switchgear, etc.) are 40 years old or older. Instabilities in the way of voltage sags and fault currents are increasing as more distributed assets are deployed on the grid. Power from renewables (solar, wind, fuel cells) is intermittent, and the same is true with energy storage systems (batteries, compressed air, hydro, etc.) with their bidirectional power flow capabilities. The challenge with higher renewable penetration is that the intermittent nature of these sources can cause sudden decreases or increases in power injected into the grid that in turn produces voltage sags and/or high fault currents. The grid needs more tools to provide reliable power, one of which is the fault current limiter.

Limitations of Conventional Solutions

The purpose of the fault current limiter device is to limit electrical surges to below the circuit breaker capacity so that the breaker never opens up unnecessarily or fails. When breakers fail, the fault current might propagate downstream and cause severe damage to utility equipment as well as interrupting service that would adversely impact large electric consumers such as manufacturing facilities, e.g. rolling mills, silicon wafer plant, etc.

Conventional utility equipment that currently mitigates this problem consists of large copper coils called line reactors. These are bulky devices that continuously consume power. For example, the traditional method for fault limiting at the distribution voltage level is with an air or oil cooled reactor in series having 2 - 5% impedance in line at a cost of $300K - $800K (5 - 80 MVA). Another fault limiting device currently used at the substation is a high impedance transformer (5 - 8% impedance) at a cost of $600K - $1100K.

Since these high impedance devices are online continuously, the electric power consumption costs of conventional fault limiting devices over the 30-year life of the device is significantly more than the initial capital costs.

Our Inductive FCL Technology

Hyper Tech is developing the inductive type FCL designed to keep the maximum fault current below the capacity of a circuit breaker; an inductive FCL is designed to store the fault energy within the coils of the device while providing the necessary impedance to limit the fault current.

Savings and Reliability

Replacing an existing air core reactor at a substation with a FCL device manufactured by Hyper Tech would not only yield potential electricity savings over 20-40 years for the electric utility company but also extend the life of the substation, particularly those that are experiencing fault conditions that are too great, thereby avoiding a multimillion dollar rebuild of the structure.

Advanced FCLs for Grid Protection and Efficiency

Hyper Tech is developing two types of fault current limiters (FCL), devices installed on the electric power grid to improve the reliability of delivering electricity to customers: one is non-superconducting for distribution level voltages, and a second type is a superconducting version for high voltage transmission.

The Challenge: A Modernizing Grid

Many of the components on the U.S. electrical grid (transformers, switchgear, etc.) are 40 years old or older. Instabilities in the way of voltage sags and fault currents are increasing as more distributed assets are deployed on the grid. Power from renewables (solar, wind, fuel cells) is intermittent, and the same is true with energy storage systems (batteries, compressed air, hydro, etc.) with their bidirectional power flow capabilities. The challenge with higher renewable penetration is that the intermittent nature of these sources can cause sudden decreases or increases in power injected into the grid that in turn produces voltage sags and/or high fault currents. The grid needs more tools to provide reliable power, one of which is the fault current limiter.

Limitations of Conventional Solutions

The purpose of the fault current limiter device is to limit electrical surges to below the circuit breaker capacity so that the breaker never opens up unnecessarily or fails. When breakers fail, the fault current might propagate downstream and cause severe damage to utility equipment as well as interrupting service that would adversely impact large electric consumers such as manufacturing facilities, e.g. rolling mills, silicon wafer plant, etc.

Conventional utility equipment that currently mitigates this problem consists of large copper coils called line reactors. These are bulky devices that continuously consume power. For example, the traditional method for fault limiting at the distribution voltage level is with an air or oil cooled reactor in series having 2 - 5% impedance in line at a cost of $300K - $800K (5 - 80 MVA). Another fault limiting device currently used at the substation is a high impedance transformer (5 - 8% impedance) at a cost of $600K - $1100K.

Since these high impedance devices are online continuously, the electric power consumption costs of conventional fault limiting devices over the 30-year life of the device is significantly more than the initial capital costs.

Our Inductive FCL Technology

Hyper Tech is developing the inductive type FCL designed to keep the maximum fault current below the capacity of a circuit breaker; an inductive FCL is designed to store the fault energy within the coils of the device while providing the necessary impedance to limit the fault current.

Savings and Reliability

Replacing an existing air core reactor at a substation with a FCL device manufactured by Hyper Tech would not only yield potential electricity savings over 20-40 years for the electric utility company but also extend the life of the substation, particularly those that are experiencing fault conditions that are too great, thereby avoiding a multimillion dollar rebuild of the structure.