Enabling Efficiency and Power Without Rare-Earth Materials

Higher Performance, Lower Cost, No Permanent Magnets

Hyper Tech has developed the technology to build high power density, highly efficient motors in the 60 kW to 3 MW range that do not use permanent magnets currently dominating the transportation motor market.

Driven by several factors, primarily a need to reduce carbon monoxide (CO) and carbon dioxide (CO2) emissions, it is becoming common knowledge that the world is moving toward electrically powered transportation. The development of electric motors powered by batteries, fuel cells or turbine generators for automobiles, buses, trucks and aircraft is rapidly accelerating. For electric motors to displace existing fossil fuel-based technology, these motors need to be configured so that they have both high power density and high efficiency in order to produce machines that are lighter weight and produce less waste heat.

The Problem with Permanent Magnet (PM) Motors

At this time, the electric motor industry is rapidly moving toward high power density and high efficiency by configuring motors with rare-earth permanent magnet (PM) rotors. However, this is a grave mistake because over 90% of the world’s rare earth PM market is controlled by one overseas country that recently consolidated all the companies in their domestic industry into one large state-owned entity. Because one country controls the PM market, they control the PM-based motor market and will control it well past 2035. Shortages of PM material are already predicted between 2025-2035, and the cost of PM material will undoubtedly skyrocket due to these shortages.

A Superior, Cost-Effective Alternative

The electric motors manufactured by Hyper Tech for the transportation industry are induction, and not designed to use PM material. Our electric motor is asynchronous (induction) configured with aluminum conductors in the rotor and stator. At ambient and cryogenic temperatures, these induction motors can meet and exceed the power density and efficiency of current and even future PM based motors. Aluminum and transformer steel are the primary materials in our induction motor, both of which are low cost and which will make ours the lowest cost option for transportation electric motors. These will be lower cost than PM motors by 30 - 40%, even if PM costs do not increase as much as expected. Power density and efficiency are driving factors in the transportation industry.

| Motor Type | Power Density (kW/kg) | Efficiency |

|---|---|---|

| State-of-the-Art PM Motors | 3-5 | ~93% |

| Future PM Motors (projected) | 8-10 | up to 97% |

| Hyper Tech Ambient Induction Motor | 8-17 | over 97% |

| Hyper Tech Superconducting Motor | Exceeds 30 | over 98% |

Covering the Full Spectrum of Power Needs

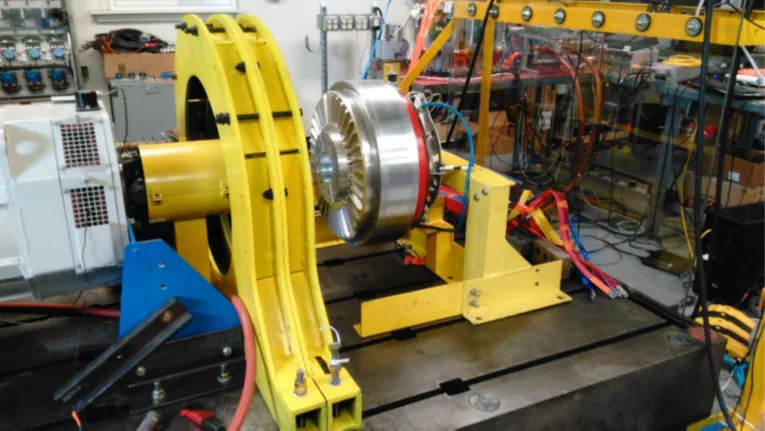

In summary, Hyper Tech potentially has motor products to cover the entire electric transportation power range. The ambient and cryogenic temperature induction motors will cover the 60 kW to 3 MW range of current and projected applications. This covers the very high-power density motors in the 2 - 10 MW range needed for single and double aisle passenger aircraft. In addition, Hyper Tech has conceptual designs for all-superconducting motors with a power density of over 30 kW/kg, again, with no PM based materials being used. We have already demonstrated a 1 MW ambient temperature motor with a world record power density of 10 kW/kg.

Ambient Temperature Motors

- 60 kW to 2 MW motors for electrified vehicles, ships and aircraft, including eVTOL

Cryo-Cooled Motors

- 1 - 3 MW motors for single and double aisle electrified aircraft.

- Higher power densities than non-cryogenic systems are enabled in machines that are designed with incorporating an advanced thermal management system (TMS) for synergistic cooling while safely utilizing liquefied bio-natural gas (Bio-LNG).

Superconducting Motors

- 2 - 10 MW motors for single and double aisle electrified aircraft.